New Cosmetic Product Development Process

Published on September 24, 2024 by Yidan Zhong

01 Definition of New Product Development

New product development begins with an idea, followed by research and feasibility analysis, leading to project planning and implementation that transforms the concept into a marketable product. New products can be categorized into newly launched products, new product lines, additions to existing lines, improvements to current products, market repositioning products, and cost-reduction products. To solidify its industry position and explore new markets, a company must select appropriate product types for development based on market changes and strategic planning.

02 New Cosmetic Product Development Process

Different types of new products have slightly different development processes due to their characteristics. However, the development process for cosmetic products can be divided into seven stages:

—Product Ideation—

Product ideation is the foundation of new product development. It often manifests as simple qualitative descriptions of unmet customer needs, emerging markets, and untapped technological potential. Consumer demand is a key source of product ideas. A development process driven by consumer needs and supported by market research effectively reduces risks and resources, making it essential for successful product development. If customer needs are unclear, companies may need to “create” new market demands for their innovative products to be accepted.

—Feasibility Analysis—

After collecting internal and external ideas, companies often develop multiple initial concepts. The purpose of feasibility analysis is to screen these concepts, eliminating those that are clearly unreasonable to reduce workload and uncertainties in the later development stages. Feasibility analysis should include:

1.Formula Feasibility: Assess if the desired product form and efficacy can be achieved with existing formulas while ensuring safety, stability, effectiveness, and usability.

2.Production Feasibility: Evaluate whether the company has the necessary equipment and filling conditions for production; if not, explore improvements or partnerships.

3.Cost Feasibility: Determine if production can be achieved within acceptable costs for formulation, packaging, production, transportation, and time.

4.Regulatory Feasibility: Confirm whether the product falls under the cosmetic category and if proposed ingredients are permissible.

5.Concept Feasibility: Assess if the product concept can be accepted by the existing consumer base; if the concept is too advanced, determine how to make it understandable to consumers.

—Project Preparation—

Once the feasibility analysis is completed and approved, project initiation can begin. A development team should be established with clear roles, such as those responsible for raw material development, formula development, physical-chemical testing, and efficacy evaluation. It’s essential that each member knows their responsibilities to facilitate smooth development. After forming the team, a project planning meeting is held to categorize products into A, B, and C classes:

A Products: High-priority items that receive significant investment. Their development plans must be approved by all relevant departments.

B Products: Standard new products requiring approval from key departments like R&D, marketing, purchasing, and training.

C Products: Mainly adjustments to existing products, which only require approval from the project leader.

—Project Execution—

With participants, development needs, and timelines clarified, the project enters the execution phase.

1. New Product Development: This includes developing formulas, concepts, packaging, and processes, along with consumer validation.

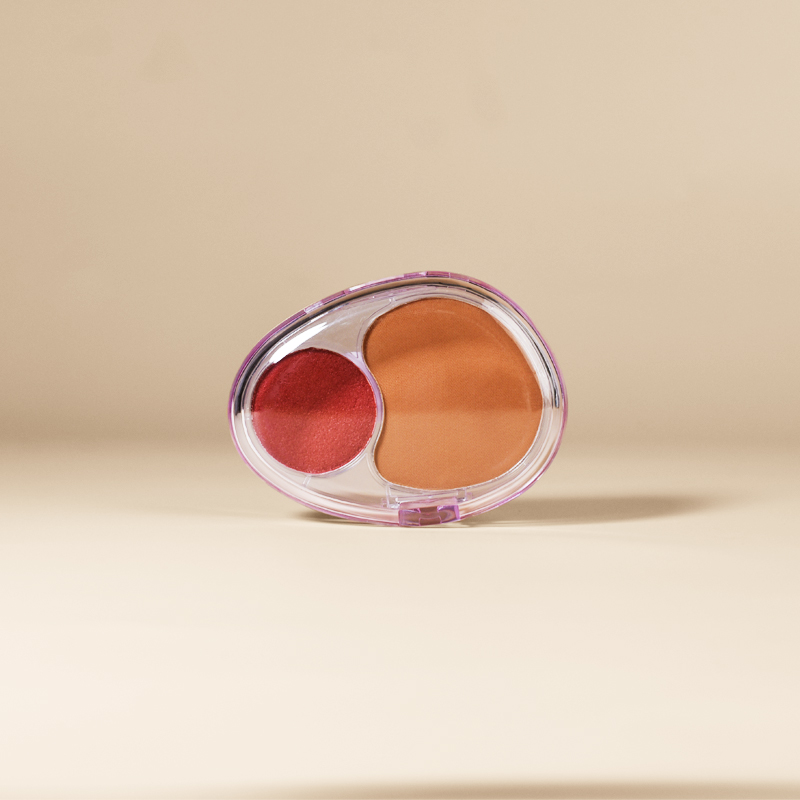

2.Formula Development: The first step is selecting the formula framework and key ingredients, considering product type, appearance, and characteristics. For instance, in serums, the type of thickener should be prioritized. The choice of ingredients impacts the product’s overall structure.

3.Concept Development: The product concept describes its appearance, function, and features, integrating skin science, formulation, efficacy, and ingredient narratives based on brand positioning and marketing strategies. Testing may be required to substantiate claims made about the product.

4.Consumer Validation: Once the formula is confirmed, target consumer volunteers (about 30-40) should test the product. If satisfaction exceeds 75%, it passes; if not, adjustments are made until the standard is met. Objective assessments may also be performed using various instruments to evaluate product efficacy.

—Market Preparation—

Before full-scale production, trial production is crucial to validate equipment, processes, and filling methods while identifying potential issues. Typically, trial production yields 50-100 kg, and the resulting product is used for stability, compatibility, safety, and efficacy evaluations, leading to the creation of a product specification document that guides quality assessment in future productions.

—Market Launch and Review—

Launching the product does not mark the end of development; follow-up and review are essential. The R&D department should summarize lessons learned from the development process and share insights internally to avoid repeating mistakes and reduce future development cycles. Ongoing monitoring of consumer feedback is necessary for continuous product improvement and quality enhancement in future upgrades.